Please be aware, this is the new Oxford Dipper Model made out of Stainless Steel. This is replacing the original Oxford Dipper and will come with a 10 year life span instead of 7 years. It is available now.

AAL LTD are accredited suppliers, installers and service providers for the Oxford Dipper Pool Hoist. We provide a complete range of lifting & handling products and services to both domestic and trade customers.

Introduction

Stephen Pritchard, Managing Director of AAL LTD is a full-time wheelchair user and is driven to supply a quality service at an affordable price. The Oxford Dipper Pool hoist is

the most predominant hoist within the UK’s NHS hospitals, Care Centres, Private

Residential Homes, Yachting & Sailing Clubs, Quaysides, Therapy &Swimming Pools and Health Centres which has a maximum SWL (Safe Working Load)

of 22 Stone (140Kg).

The Dipper uses a hydraulic pump

to raise and lower service users and gives the support workers and service

users peace of mind as it’s not reliant on electricity. To operate the hoist, simply pump the

hydraulic pump using the handle to raise the user and to release, unscrew the

black pump valve to slowly lower the service user.

There are two variations of the

Oxford Dipper Pool Hoist, the standard Oxford Dipper with spreader bar and the

Oxford Dipper with Ranger seat. Both variations are available with an array of

sockets to meet each individual customers specification.

Oxford Dipper Pool hoist with Spreader Bar

The spreader bar version is

designed for service users who use a sling with loops to access the pool etc. The

service user will access the pool via a wheelchair and wheel up to the

spreader bar. The support person will

fit the sling and once ready, raise the dipper by pumping the arm to a height

that will enable the sling to be attached and thus raise the service user off

the wheelchair. The user will then be suspended by the supporting sling, this

person can then be safely lowered into the pool by unscrewing the black dipper

release valve into the pool.

Can you have both options on one Dipper?

There are two types of Oxford Dipper boom extensions, the 6 point spreader bar and the Ski tube which is compatible with the Oxford Ranger Seat. The 6 point spreader bar is used with slings, slings with loops, not clips. The spreader bar is very easy to attached, it takes 2 minutes.

The Ski Tube connects again, very easy. This enables the Ranger seat to reverse up to lift, connect and lift with ease within a few minutes. To demonstrate how easy it is to connect these attachments, we've created a couple of short videos for your convenience.

How do you connect the Oxford Dipper Spreader Bar?

How do you connect the Oxford Dipper Ski Tube for the Ranger seat?

How is the Dipper fitted to the floor?

The Dipper comes with three (3)

options. Socket A, B and C. The sockets

are ergonomically designed to be fit for different materials and finishes

enabling the Oxford Dipper to be installed in almost any pool side setting. For

more information on the socket fittings, please visit our website here.

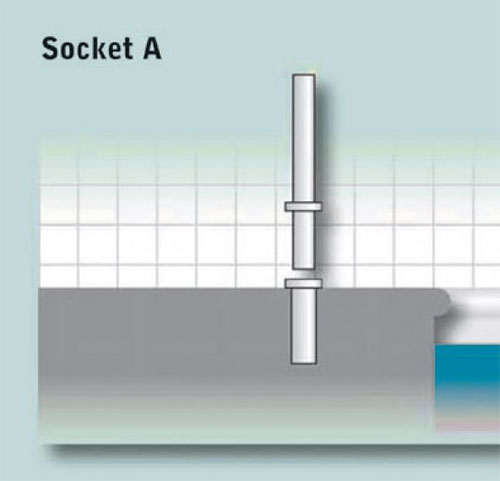

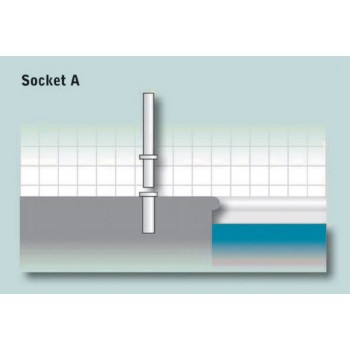

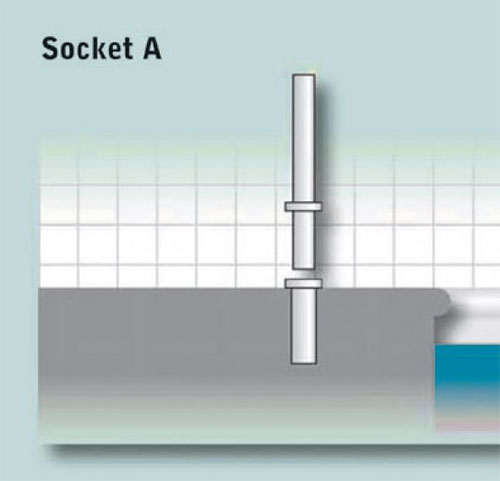

Socket A for Oxford Dipper

To fit the socket A, a 1M sq cube

of concrete is required as the minimum recommendation. If already installed, a 91mm hole then needs

to be drilled 350mm deep.

An accredited engineer will then

install the sockets interior, casing and socket cap which will then sit flush

with the floor.

The Dipper then slots into the

socket when in use and once the use has been completed or you wish to store

away, simply slide the dipper out of the hole ensuring you have lowered the

boom to its lowest point and with the dipper strap, secure the pump tightly to

the mast. This will prevent damage to the mast, pump and release valve when

transporting the dipper to storage.

After use please ensure the

dipper pump is lowered to its lowest possible position, this ensures that the

chrome on the hydraulic pump remains oiled and rust free and therefore

extending the service life of the hoist. Should the hoist not remain oiled, the

chrome will become pitted and this will destroy the internal seals over a long

period of time, a new hydraulic dipper pump costs approx. £500.00 exclusive of

vat.

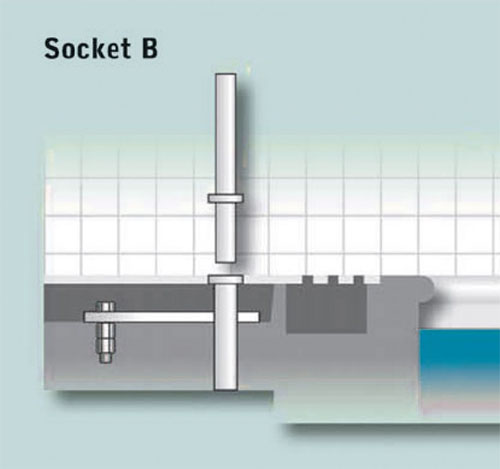

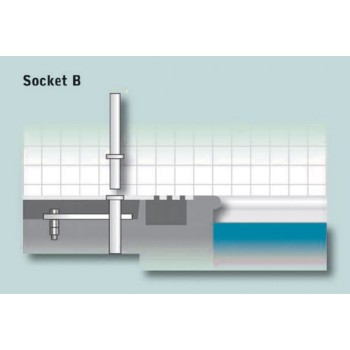

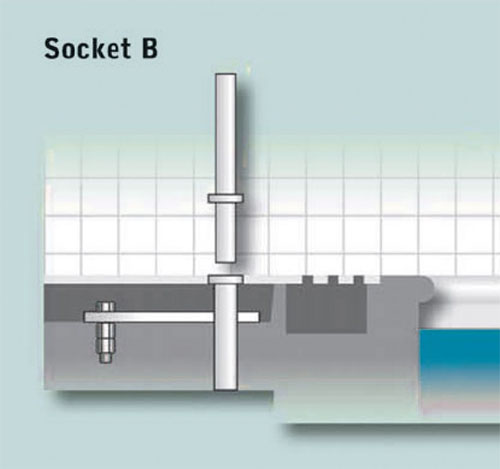

Socket B for Oxford Dipper

Socket B is fitted and installed

as shown in the picture above, socket B is primarily used in swimming pools

which have a water channel around that outlines the perimeter of the pool.

Socket B is a replica of socket A with an added base plate which adds

additional bracing and support to the Oxford Dipper.

The B socket plate is fixed into

place with six 15mm diameter expanding bolts of the rawplug type, for more

information please see the socket construction as illustrated above.

As with the A socket, the B

socket is slightly below floor level and is fitted with a blanking plug. The

blanking plug can be inserted into the hole when the Oxford Dipper is

transported away for storage, this leaves a clean flush finish to the pool

sides surface, minimising injury and maximising hygiene in the pool area.

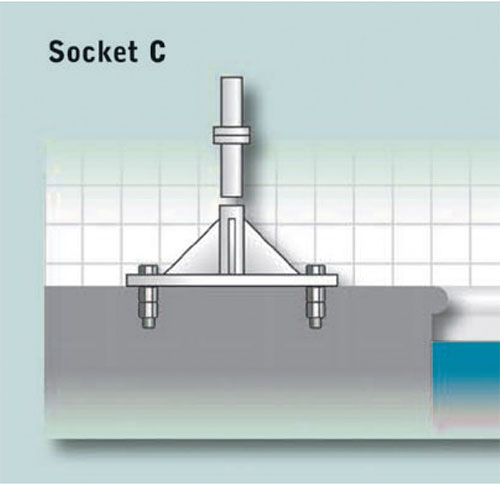

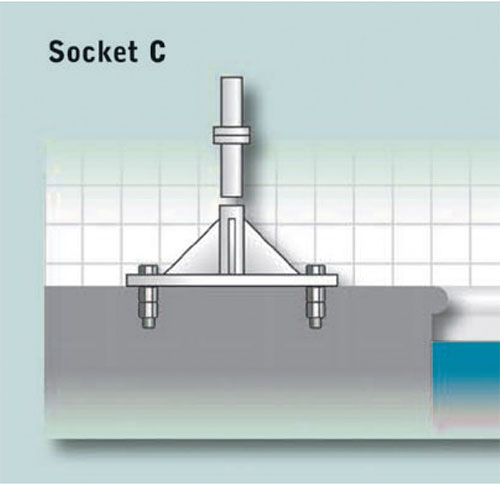

Socket C for Oxford Dipper

Socket C is surface mounted and stands

proud of the floor by approx. 150mm, this socket is used mainly where there is

insufficient depth of concrete for sockets A or B.

The C socket plate is drilled

with four 15mm Rawplug type expanding bolts, the recommended minimum depth of

concrete to enable an accredited engineer to install the hoist is 150mm.

Due to the pretruding nature of

the socket, socket C adds 150mm to the overall height of the hoist and

therefore alters the maximum height of the bottom of the chair to 1039mm and

the lowest position of the chair bottom below floor level to 764mm. For more information, please see the

illustration found above.

Servicing, Parts and Maintenance

AAL LTD offers a suite of service

and maintenance packages to suit your ue and needs, the following

description below is a brief guideline of our services:

A 3.1 service contract plan

offers you an annual service inclusive of the required LOLER test and

certificate and the appropriate weight testing for three (3) consecutive years.

A 3.2 service contact plan offers

you a six (6) monthly inspection, followed by a six (6) monthly service inclusive

of the required LOLER test and certificate and the appropriate weight testing

for three (3) consecutive years.

As we are an accredited Oxford UK

Dealer, we are able to offer you the complete range of spare parts for allOxford products here. Should you require any advice or assistance

then please do not hesitate in calling us on 01772

814555, we are here to help!